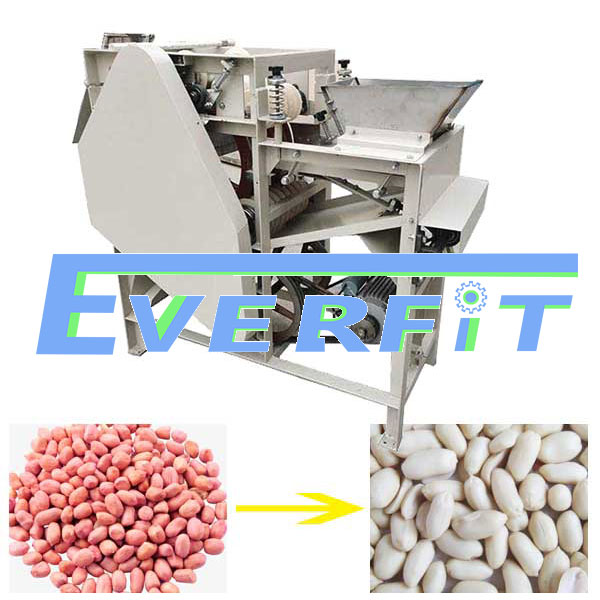

The peanut wet peeling machine adopts rolling and rubbing to peel the peanuts. It has stable and reliable performance, long service life and good peeling effect. It is suitable for processing peanuts of various specifications and varieties. To better play the role of the peanut wet peeling machine, maintenance is essential. Today, Everfit learned about the specific maintenance methods from the three stages of the peanut wet peeling machine at the end of the operation, repair and processing seasons, hoping to help you.

1.During work

During the operation of the peanut wet peeling machine, you should always observe whether the speed, sound, and temperature of the equipment are normal; after a day's operation, you should stop the machine to check whether the bearings are overheated, and whether the fastening screws and key pins of each part are loose. If it is found to be loose, it should be tightened at any time, especially the high-speed parts. The blades of the following fans are easy to wear or break, and the reinforcing plates used outside the blades are easy to wear or deform. Once problems are found, they should be repaired or replaced in time.

2. During repair

In the process of repairing the peanut wet peeling machine, the tires of the equipment need to be corked with triangle wood. After using the jack to lift the peanut wet peeling machine, you should also increase the support tool to hold it firmly; before loosening the jack, pay attention to whether there are people or obstacles beside you; check the pipeline of the hydraulic tank, only after the inclined peeling box is firmly supported conduct.

3. After the processing season

After the processing season, a major inspection of the equipment should be carried out. First, check the operation and wear of the drum shaft, eccentric shaft, and fan shaft; secondly, check whether the screen bottom is deformed or cracked; then check the wear of the sorting screen. After the inspection, the damaged parts should be repaired, the dirt and residual peanuts in the equipment should be removed, all the bolts should be tightened, all the bearings should be oiled, the belt should be removed, and the accessories should be put into storage for use in the next season.

Mobile/Whatsapp 0086-18695800088

Mobile/Whatsapp 0086-18695800088